One of the most consumed foods in the world as an appetizer or snack is the potato chip in its different forms, smooth potato, wavy, stick, etc… They are obtained from fresh potatoes after going through a process of washing, peeling, cutting, defecated, bleacher and fried in oil or edible fats and subsequently flavored and packaged for sale.

In ARAIT® we offer our clients complete solutions for potato processing from its arrival from the field to its final packaging. Our continuous potato chip processing lines are fully automated and designed for easy cleaning.

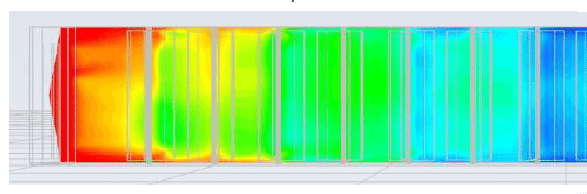

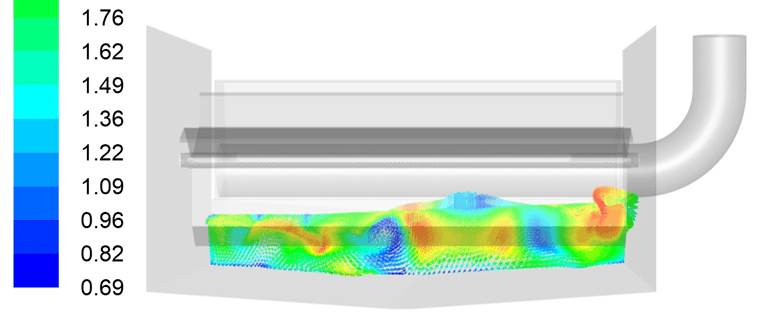

Thanks to our extensive experience and the use of the latest computer-assisted simulation technologies for the behavior of oil in the potato chip fryer, we can affirm that our potato chip frying lines are characterized by:

- Great care of the vegetable oil used in frying potato chips.

- Great quality of the final potato chip.

- Reduced consumption of water in the line.

We have standard potato chip processing lines with productions ranging from 300 Kg/h to 1,000 Kg/h of finished product. For other productions we also have customized solutions.

Parts of fried potato chip line:

The potato enters the line through a hopper with a motorized outlet and goes through a screening process, removal of roots and foreign bodies, and washing prior to the peeling process.

The potato, once washed, is peeled through our fully automated centrifugal abrasion peelers. Once peeled and after another wash, the peeled potato is transported on our inspection belts for manual selection.

To cut the potato to its final version, whether chip, corrugated or stick, we use leading brand cutters such as Urschell or FAM, adapted to our production line. The cut potato is washed with water at room temperature to reduce its starch content and eliminate small pieces that may appear after cutting.

Depending on the variety of potato, its sugar content and customer needs, it is optional to subject the cut potato to a second controlled high-temperature washing process to achieve a better finished product.

After a drying process, the sliced potato reaches the potato chip fryer where, thanks to our innovative multi-flow oil system, the sliced potato is fried to obtain a final product with ideal characteristics of flavour, texture and colour. The use of an indirect heat exchanger system allows precise control of the frying temperature.