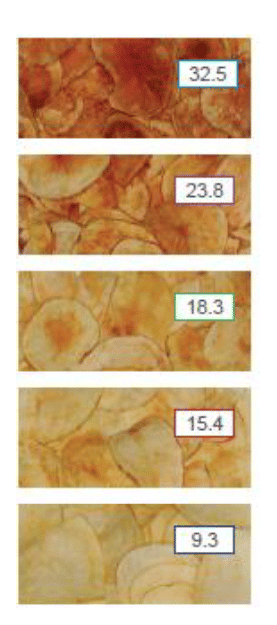

For any manufacturer of food products, one of the most important points is being able to know the quality of their finished product at all times. More specifically, in the case of manufacturers in the fried appetizers sector, being able to measure in real time the moisture parameters of the product, its oil content and even the degree of toasting provide them with essential information to guarantee the quality of their food. product. Until now, the only solution to be able to measure these parameters was taking samples and processing them in a laboratory to obtain these measurements. With the appearance of near infrared measurement systems without contact with the product, this gap has been filled and allows us to obtain in real time the quality parameters of the snack when it comes out of the fryer, with precision errors of less than 1%.

In view of the above and thanks to the latest technological advances, at ARAIT® we offer the possibility of integrating online NIR meters into our lines for frying potato chips, snacks, nuts and corn. As an added value to the above, the data collected by the sensor is integrated into our automation system and allows us both to save it permanently and to generate the necessary warnings and alarms in the event that any measurement is outside the permitted range.

With an IP67 degree of protection and made of 316 quality stainless steel, our measurement equipment can be installed directly at the outlet of our potato chip and snack fryers safely and in compliance with the strictest standards.